Contents

DEFINITIONS

G26.1 Definition of resource roads

G26.1-1 Forestry operations and similar activities

GENERAL REQUIREMENTS

G26.1-2 Owners' obligations

G26.1.1-2 Prime contractor obligations

G26.2-1 Planning and conducting a forestry operation

G26.2-2 Planning log hauling operations for varying road grades

G26.2-3 Multiple cuts - Mechanical falling

G26.3.1(1)(a) Acceptable standard for training

G26.11 Wildlife dangerous tree assessment

EQUIPMENT OPERATION

G26.16 Slope limitations – Safe work procedures

G26.18 Acceptable standards for landslide risk assessments

MANUAL FALLING AND BUCKING

G26.21/26.22 Faller training – Application

G26.21-1 Arborist qualifications

G26.21-2 Faller qualifications – Performance upgrade

G26.22(7) Forestry operation faller training – Challenge process

G26.28 Summoning qualified assistance

TRAFFIC CONTROL FOR FALLING OPERATIONS

G26.30 Traffic control when falling a tree

YARDING

G26.41 Guylines

HAULING

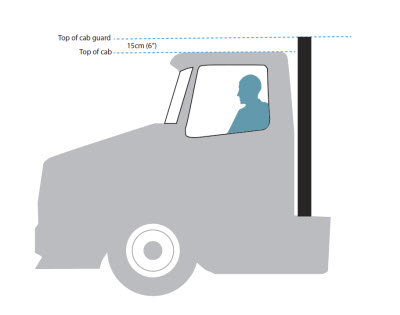

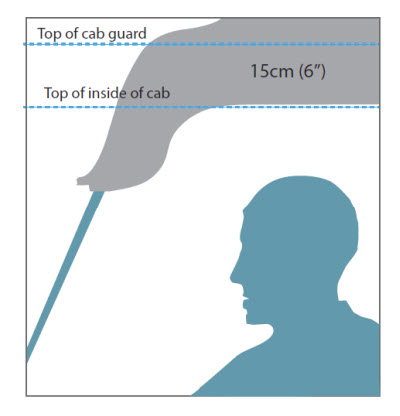

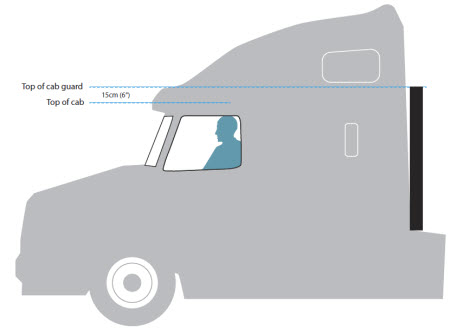

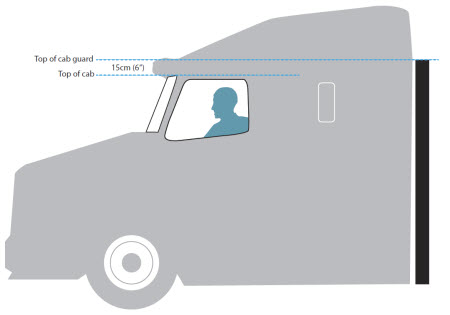

G26.65 Determining cab guard compliance

G26.65(1) Certified welding inspector – Alternate standards

G26.65(2)(e) Installing the cab guard on the log transporter in a manner acceptable to WorkSafeBC

G26.65(4) Log transporters pulling multiple trailers

G26.65(4)(b) Installing the barrier on the logging truck in a manner acceptable to WorkSafeBC [Withdrawn]

G26.68 Binder cinches [retired]

G26.69(2)(c) Safe work procedures for the use of a removal station

Guidelines Part 26 - Definitions

G26.1 Definition of resource roads

Section 1.1 of the Regulation exempts resource roads from being considered a workplace. For further discussion please refer to OHS Guideline G1.1(1).

G26.1-1 Forestry operations and similar activities

Issued May 1, 2008

Regulatory excerpt

Section 26.1 of the OHS Regulation ("Regulation") states:

"forestry operation" means a workplace where work is done in relation to silviculture or harvesting trees, including constructing the means of access and transporting the harvested trees to a facility where they are processed or from which they are exported.

Purpose of guideline

The purpose of this guideline is to describe the scope and application of the requirements of Part 26 of the Regulation.

"Forestry Operations and Similar Activities" and the application of Part 26

The title of Part 26 of the Regulation is "Forestry Operations and Similar Activities." This title reflects the intent to capture in the scope of Part 26 not only those workplaces that are involved in forestry operations as defined in section 26.1, but operations that have similar characteristics, hazards, and work processes.

The application of a specific provision in Part 26 will depend on the wording of the particular section. Certain provisions in Part 26 will state that they relate only to "forestry operations," while others will not be limited by the use of this term.

For example, section 26.2 requires all aspects of a forestry operation to be "planned and conducted in a manner consistent with this Regulation." This section would only apply to owners of workplaces that fall within the definition of a forestry operation by being workplaces "where work is done in relation to silviculture and harvesting trees… "

In contrast, section 26.21 states that "a worker must not fall trees or be permitted to fall trees…" unless the worker is qualified and only performs work within the worker's documented capabilities, and does not restrict itself to workers in a "forestry operation." As this section does not refer specifically to forestry operations, it can be applied more broadly to both forestry operations and similar activities.

What is work relating to "harvesting trees"?

The definition of "forestry operation" includes "work done in relation to … harvesting trees." WorkSafeBC considers work relating to "harvesting trees" to be any operations that are undertaken pursuant to a permit, license, or other tenure or permission from the Ministry of Forests or other government agency. In particular, this includes any falling activity on land designated as provincial forest, which includes Crown forest land, range land, or private land that is subject to a tree farm license, community forest agreement, or a woodlot license. "Forestry operations" may also include any falling that is done on private land that is not subject to a timber tenure, provided that the harvesting is undertaken as part of an enterprise that has as a purpose falling trees for the purposes of selling or processing them to be made into merchantable wood products.

For greater certainty, WorkSafeBC considers the following to involve "harvesting trees" and to therefore be "forestry operations":

- Harvesting timber for processing or sale either pursuant to a license or permit from the Provincial Government, or on a private woodlot

- Falling trees in connection with forest fire fighting or fire prevention activities

- Falling trees in connection with oil and gas exploration and site preparation, including seismic line falling

Workers who exclusively fall trees that measure less than 15cm (6") diameter at 30cm (12") height are not considered to be engaged in harvesting trees.

"Similar activities"

Certain types of operations that do not fit the definition of "forestry operations" in section 26.1 may present similar types of working conditions and hazards as forestry operations. Despite not being "forestry operations," it is appropriate that certain elements of Part 26 apply to these operations, given the similarities. For example, an arborist crew that falls trees in order to maintain rights of way for electrical conductors in remote locations will perform work very similar to a typical forestry operation, though, depending on the type of work they are doing, they may not fall within the definition of a "forestry operation." In such a case, there must be compliance with the procedures for falling and bucking in sections 26.23 through 26.29, as those sections are not specific to "forestry operations," though a Notice of Project under section 26.4 need not be filed, as that requirement is limited to certain forestry operations.

Guidelines Part 26 - General Requirements

G26.1-2 Owners' obligations

Issued May 1, 2008; Revised November 29, 2012; Editorial Revision April 6, 2020

Regulatory excerpt

Section 25 of the Workers Compensation Act ("Act") states:

Every owner of a workplace must

(a) provide and maintain the owner's land and premises that are being used as a workplace in a manner that ensures the health and safety of persons at or near the workplace,

(b) give to the employer or prime contractor at the workplace the information known to the owner that is necessary to identify and eliminate or control hazards to the health or safety of persons at the workplace, and

(c) comply with the OHS provisions, the regulations and any applicable orders

Section 26.1.1 of the OHS Regulation ("Regulation") states:

If the owner of a forestry operation enters into an agreement referred to in section 13 of the Act designating a person to be the prime contractor for a workplace, the owner must ensure that

(a) the person designated

(i) is qualified to be the prime contractor in respect of that workplace, and

(ii) has the authority necessary to fulfill the responsibilities of prime contractor under the Act, including, without limitation, authority over any employer, worker or other person who may be carrying out the work of the owner at the workplace, and

(b) not more than one person holds the designation of prime contractor for that workplace at any given time.

Section 26.2(1) of the Regulation states:

The owner of a forestry operation must ensure that all activities of the forestry operation are both planned and conducted in a manner consistent with this Regulation and with safe work practices acceptable to the Board.

Purpose of guideline

The purpose of this guideline is to provide information regarding obligations on owners of forestry workplaces.

"Owners" - Who is an owner?

A number of requirements in Part 26 relate specifically to the "owner" of a forestry workplace or forestry operation. Section 25 of the Act also sets out general responsibilities of owners, and section 24 of the Act will create prime contractor obligations on owners of multiple employer workplaces that do not designate a prime contractor.

The definition of owner in section 13 of the Act expands the commonly understood meaning to include a "licensee or occupier of any lands or premises used or to be used as a workplace" or "a person who acts for or on behalf of an owner as an agent or delegate." Accordingly, a number of parties may be owners of a forestry workplace.

Both the Ministry of Forests, Lands, and Natural Resource Operations (MFLNRO) and those that hold forest tenures are considered to be owners of workplaces where forestry operations are undertaken.

Most forestry in British Columbia takes place on publicly owned Crown lands managed by the province through the MFLNRO. The MFLNRO grants rights to harvest and market timber to licensees through a variety of types of licenses, or tenures. The MFLNRO is an administrative department of the Crown and does not have a separate legal identity from the Crown. As the workplace for almost all forestry operations will be located on Crown lands, the MFLNRO should be considered an owner of workplaces in which forestry operations are taking place.

In addition, licensees and holders of forestry tenures administered by MFLNRO will also be considered to be owners. The definition of owner, which includes licensees and occupiers of lands, clearly includes these workplace parties.

Which owner is responsible for which obligations?

Where there are multiple owners of forestry workplaces, it is necessary to determine which owner is responsible for which obligation. Policy Item P2-25-1 sets out the factors to consider in determining each owner's responsibility in a multiple-owner situation. These factors relate to the knowledge of workplace hazards, control over the workplace, and the reasonableness of imposing the particular obligation on that owner.

In accordance with Policy Item P2-25-1, WorkSafeBC prevention officers should consider issuing orders to owners where the owner has knowledge and control over the workplace hazards in question. Among the factors to be considered in issuing orders to owners are:

- Knowledge: whether the owner knew or should have known that the health and safety of the persons at or near the workplace would likely be harmed by the condition or use of the workplace and the extent of the harm, if it occurred, would be more than minor or trivial.

- Control: whether the owner had some control or influence over the safety of the workplace in that the owner could practicably have taken measures necessary to eliminate or reduce the risk or extent of the potential harm.

For example, determining responsibilities of MFLNRO and licensees will necessarily reflect the control over forestry workplaces administered by the tenuring system. MFLNRO's control over safety would be relatively indirect, as licensees are positioned to have the predominant control over the high level planning of work in most forestry workplaces. MFLNRO has control over the allocation of the tenure as well as monitoring the performance of its licensee; and its obligations as owner will centre on how tenures are allocated and will provide appropriate information around hazards encountered in monitoring these tenures. - Communication: whether the owner possessed material information and failed to communicate all the material information in the owner's possession to the persons at or near the workplace, thus preventing them from taking measures to protect themselves.

These factors assist in determining which obligations each owner will have under section 25 of the Act as well as under section 26.2 of the Regulation. For example, a licensee that prepares a harvesting plan that includes areas that present hazards from steep slopes must provide information to harvesting contractors that identifies these areas so that harvesting can be planned and undertaken in a way that deals appropriately with that hazard.

Which "owner" may designate the prime contractor?

With respect to multiple-employer workplaces, the obligations of the prime contractor under section 24 of the Act must be fulfilled by "the owner" of the workplace, if the owner does not designate a prime contractor. In addition, section 26.1.1 of the Regulation imposes certain requirements on the owner who designates a prime contractor for a forestry workplace. As a practical matter, it is only possible to have one owner who may designate a prime contractor, or who must fulfill that role if none is designated.

In accordance with Policy P2-25-1, it will be the owner with the most control over and knowledge of a particular workplace who must fulfill the obligations of section 24 of the Act, or who may designate a prime contractor. In making this determination, the elements of knowledge and control should relate to the ability to plan and manage the workplace as a whole. That is, the owner that may designate a prime contractor or who must act in that capacity if none is designated, will be the owner that has the most ability to control how work is done by others at the workplace, and who has the most knowledge of how work is to be done in general.

Licensees will normally have the most knowledge of and control over forestry workplaces, and therefore it will be reasonable in most situations to view licensees as the owners with the most responsibility over forestry workplaces. For most forestry operations, the licensee will be the owner for the purposes of section 26.1.1 and section 24.

That said, where the MFLNRO retains primary control over certain multiple-employer workplaces, it will be the primary owner and prime contractor where none is designated. This may include multiple-employer workplaces such as small business sales through the BC Timber Sales program.

Though licensees are the primary owners of forestry workplaces, MFLNRO retains some owner obligations. MFLNRO compliance with obligations in section 25(a) of the Act to "provide and maintain…. land and premises that are being used as a workplace in a manner that ensures health and safety" will to a great extent be shaped by the legislation governing the disposition of forest licenses and the terms of the license granted by MFLNRO to the licensee.

With respect to the obligation in section 25(b) of the Act to give "information… necessary to identify and eliminate or control hazards…," the MFLNRO should typically be expected to communicate to licensees, prime contractors, or any relevant employer in a license area, information about any safety hazard it becomes aware of, or should have become aware of, particularly with respect to hazards encountered during the course of inspecting forestry operations to ensure that the terms of the forest license and forestry legislation are being adhered to.

G26.1.1-2 Prime contractor obligations

Issued May 1, 2008; Revised November 29, 2012; Editorial Revision April 6, 2020

Regulatory excerpt

Section 26.1.1 of the OHS Regulation ("Regulation") states:

If the owner of a forestry operation enters into an agreement referred to in section 13 of the Act designating a person to be the prime contractor for a workplace, the owner must ensure that

(a) the person designated

(i) is qualified to be the prime contractor in respect of that workplace, and

(ii) has the authority necessary to fulfill the responsibilities of prime contractor under the Act, including, without limitation, authority over any employer, worker or other person who may be carrying out the work of the owner at the workplace, and

(b) not more than one person holds the designation of prime contractor for that workplace at any given time.

Section 13 of the Workers Compensation Act ("Act") states:

"multiple-employer workplace" means a workplace where workers of 2 or more employers are working at the same time;

"prime contractor", in relation to a multiple-employer workplace, means

(a) the directing contractor, employer or other person who enters into a written agreement with the owner of the workplace to be the prime contractor for the purposes of the OHS provisions, or

(b) if there is no written agreement referred to in paragraph (a), the owner of the workplace;

Section 24 of the Act states:

(1) the prime contractor of a multiple-employer workplace must

(a) ensure that the activities of employers, workers and other persons at the workplace relating to occupational health and safety are coordinated, and

(b) do everything that is reasonably practicable to establish and maintain a system or process that will ensure compliance with the OHS provisions and the regulations in respect of the workplace.

(2) Each employer of workers at a multiple-employer workplace must give to the prime contractor the name of the person the employer has designated to supervise the employer’s workers at that workplace.

Purpose of guideline

The purpose of this guideline is to provide information on prime contractor obligations, including how to determine the scope of a workplace to evaluate whether prime contractor obligations must be fulfilled, and what qualifications a prime contractor must have.

The prime contractor designation - What is "the workplace"?

Forestry workplaces will often be multiple-employer workplaces. This means that the obligations under section 24 of the Act relating to coordinating and maintaining a system of compliance must be fulfilled, either by a prime contractor, or if none is designated, the owner.

Section 13 of the Act defines "workplace" broadly. It states:

"workplace" means any place where a worker is or is likely to be engaged in any work and includes any vessel, vehicle or mobile equipment used by a worker in work.

In typical commercial or industrial operations, what constitutes the workplace is often self-evident, as the location is well defined. With respect to forestry operations, which involve a variety of activities undertaken by a range of contractors over a broad geographical area, identifying the workplace is less certain. Work locations may be undefined until the work is actually performed, and may be located anywhere within the licensed area.

Policy Item P2-24-1 ("Policy") provides that a multiple-employer workplace may exist even if workers of different employers are present at the same time working on different projects. In addition, the Policy provides that the phrase "at the same time" will be given a "fair large and liberal construction" in order to "best attain the objectives of section 24." According to the Policy, "at the same time" means that workers of two or more employers are merely present in the workplace over "an appropriate interval" rather than at any precise point in time, and that the duration of the interval of time to be considered will depend upon the circumstances of the individual workplace. In addition, the Policy provides that it does not matter whether the workers of the different employers actually come into contact, as long as one employer's workers and their activities could well affect the health and safety of another employer's workers who come into the workplace at some other time.

Assessing what the workplace is for the purposes of establishing prime contractor obligations in the forestry industry will, in addition to the factors outlined in the Policy, depend on the following:

- The degree to which the activities of one employer will impact the health and safety of workers of another employer in a given area

- The degree to which a given area constitutes a single contiguous administrative unit

- Exclusivity of control over the given area

The multiple-employer workplace may, depending on the circumstances, be a single block, a cutting permit area, or, in certain situations where the above factors are present, an entire licensed area.

Section 1.1 of the Regulation exempts resource roads from being considered a workplace. For further discussion please refer to OHS Guideline G1.1(1).

Section 13 of the Act provides that the prime contractor will be the owner, unless there is a specific agreement designating another person as the prime contractor. As the owner with the greatest control over the workplace, it is appropriate that the licensee act as the "default" prime contractor. Even though there may be a "stump to dump" contractor who may be a directing contractor over a broad portion of forestry operations, that contractor will not be the prime contractor unless there is a specific designation in a written agreement that the contractor will act as prime contractor for the purposes of coordinating occupational health and safety matters.

Also, in accordance with Policy Item P2-24-1, there can be only one "prime contractor" at a workplace at any point in time. If an owner enters into more than one agreement purporting to create a "prime contractor " for the same period of time, the owner will be considered to be the prime contractor.

For information on which owner may designate the prime contractor, please refer to OHS Guideline G26.1-2.

"Qualified"

Section 26.1.1 states that the owner must ensure the prime contractor at a multiple-employer forestry workplace is qualified. "Qualified" is defined in section 1.1 of the Regulation as "being knowledgeable of the work, the hazards involved and the means to control the hazards, by reason of education, training, experience or a combination thereof." Multiple-employer forestry workplaces will involve a complex mix of work activities and hazards. Owners are therefore expected to ensure that prime contractors they designate have a significant level of experience and training specific to the types of operations that they will be coordinating. Being "qualified" also involves possessing knowledge of how to control hazards; a qualified prime contractor must not only have knowledge of work processes, but knowledge of hazard recognition and managing health and safety risks.

Note that under section 24 of the Act, the owner must agree in writing with the prime contractor that the prime contractor will act in that capacity. The prime contractor must be aware that it has agreed in writing to act in that capacity, and the language of the agreement must be adequately clear that the parties intended that the prime contractor act in that capacity. Failure to have an adequate written agreement will result in the owner being required to fulfill the prime contractor obligations.

What are the obligations?

Under section 24(1) of the Act, the prime contractor is responsible for coordinating activities relating to health and safety at the workplace. Coordination will extend to logistical matters relating to the work carried out by the employers at the workplace. The prime contractor of a forestry workplace must, as a function of this coordination role, perform a risk assessment to determine appropriate measures to eliminate or reduce hazards faced by workers in the area in question.

The prime contractor is also responsible for establishing a system or process to ensure health and safety compliance. This may involve establishing a safety program as described in the OHS provisions, Division 4 of the Act and section 3.3 of the Regulation with respect to the entire workplace, as well as making regular inspections of the workplace as contemplated by section 3.5 of the Regulation. It may also involve the creation of a joint health and safety committee for the entire workplace. At a minimum, prime contractors should ensure that things like the initial safety meeting under section 26.5 and the orientation of young or new workers under section 3.23 take place. In addition, a necessary feature of any system or process is the ability to monitor and maintain that system. A prime contractor must take steps to ensure the employers it is coordinating are complying with and participating in its system.

In addition to the duties on prime contractors contained in the Act, section 26.4 of the Regulation requires the prime contractor to submit a notice of project of a forestry operation.

G26.2-1 Planning and conducting a forestry operation

Issued May 1, 2008; Revised November 29, 2012; Editorial Revision April 6, 2020

Regulatory excerpt

Section 26.2 of the OHS Regulation ("Regulation") states:

(1) The owner of a forestry operation must ensure that all activities of the forestry operation are both planned and conducted in a manner consistent with this Regulation and with safe work practices acceptable to the Board.

(2) Every person who has knowledge and control of any particular activity in a forestry operation must ensure that the activity is both planned and conducted in a manner consistent with this Regulation and with safe work practices acceptable to the Board.

(3) The planning required under this section must

(a) include identification of any work activities or conditions at the workplace where there is a known or reasonably foreseeable risk to workers,

(b) be completed before work commences on the relevant activity, and

(c) be documented at the time of planning.

(4) If, after any planning referred to in subsection (3), there is a change in the workplace circumstances, including the work activities and the conditions of the workplace, and the change poses or creates a known or reasonably foreseeable risk to workers that was not previously identified, then

(a) the plan must be amended to identify and address the risk and provide for the health and safety of the workers at the workplace, and

(b) the amendment must be documented as soon as is practicable.

Purpose of guideline

This guideline provides guidance to WorkSafeBC prevention officers as well as stakeholders in the forest industry regarding accountability and responsibility for aspects of planning and conducting operations to ensure health and safety compliance in forestry operations.

Background

Most forestry in British Columbia takes place on publicly owned Crown lands managed by the province through the Ministry of Forests, Lands and Natural Resource Operations (MFLNRO). The management of the forests and lands in which forestry operations take place is governed by a variety of legislation, including the Forest Act and the Forest and Range Practices Act and regulations associated with these Acts.

Under this legislation, the MFLNRO grants rights to harvest and market timber to licensees through a variety of types of licenses or tenures. These licenses also place certain obligations on the licensees. In general the terms of the license include conditions relating to harvesting practices, forest management, road building, reforestation, firefighting, and the like. Certain terms are dictated by forestry legislation; certain terms are functions of MFLNRO policy.

Historically, timber harvesting and related operations, particularly on the coast, were typically carried out directly by the licensee. In recent years, however, forest operations have evolved into a complex multi-layered mix of contractors, subcontractors, and independent operators. In the interior, the evolution has been less dramatic, as in that regional operations have historically involved a wide variety of contractors, often provided for in the tenures provided to licensees.

The MFLNRO determines an Annual Allowable Cut (AAC) for a particular broad region of the province, called a Timber Supply Area. This area may include any number of licenses, and provides specific authority to licensees to harvest certain areas included in their respective license area through specific cutting permits.

Licensees tend to contract operations related to harvesting and forest management to subsidiary organizations or to third-party contractors. In particular, licensees will often contract with subsidiaries or third-party contractors to oversee harvesting operations in specific areas (referred to as "blocks") within the cutting permit area. Such contractors (often referred to as "stump to dump" contractors) are often responsible for a wide range of operations with respect to a given cutting permit.

Those organizations, in turn, tend to contract out portions of the harvesting operations (such as falling, yarding, or timber transportation) within specific blocks to subcontractors (often referred to as "phase" contractors). Those subcontractors, in turn, may engage individuals such as fallers or equipment operators to perform specific tasks. These individuals might be employees under a contract of service or independent contractors, who also may engage other workers as employees or under contract.

All of these different organizations and individuals have responsibilities for ensuring forestry operations are planned and conducted in a manner that ensures the health and safety of forest workers.

"Planning and conducting" and the contracted out forestry workplace

Section 26.2(2) of the Regulation requires every person who has knowledge of and control over any particular activity in a forestry operation to ensure that the activity is both planned and conducted in a manner consistent with this Regulation and with safe work practices acceptable to WorkSafeBC.

The health and safety at forestry workplaces is the responsibility of all workplace parties that have an influence on how work is conducted. Section 26.2(2) reinforces that idea by requiring each person in a forestry operation to plan and conduct activities that they have knowledge of and control over. This obligation lies with all workplace parties. For example, the MFLNRO must ensure that access to Crown lands is provided in an adequately planned way so that workers of different tenure holders are not placed at risk. Licensees must plan overall operations in a manner that ensures that work can be carried out with a minimum of risk. Workers, for their part, must carry out their work in a manner that protects their own safety and the safety of other workers.

With respect to work that is to be provided under contract, "plan and conduct" should include the following obligations:

- Evaluating the risks the operations of contractors at one workplace within the license area will impose on the workers at another, and, where necessary, coordinating those activities in order to ensure that health and safety of workers is not put at risk.

- Monitoring the operations of contractors to ensure that they are meeting their health and safety obligations and are, in turn, monitoring the health and safety performance of their subcontractors. As noted above, where the contracting employer appoints a contract supervisor, that individual should monitor compliance with health and safety requirements as a function of his or her duties to monitor compliance with the terms of the contract.

Obligation of employers to workers of different employers

In considering the importance of planning and conducting work in contracted out forestry workplaces, it is important to note the obligation of section 21(1)(a)(ii) of the Act, which states:

21(1) Every employer must

(a) ensure the health and safety of

(i) all workers working for that employer, and

(ii) any other workers present at a workplace at which that employer's work is being carried out...

This section requires that every employer must ensure not only the health and safety of its workers, but also the health and safety of "any other workers present at a workplace at which that employer's work is being carried out."

A given work activity is not necessarily merely the work of the direct employer of the workers carrying out the work. The work may also be considered to be the work of an employer that has engaged a contractor instead of having its own workers carry out that work.

With respect to forestry operations, the entire range of activities relating to timber harvesting, transportation, and forest management should be viewed as the licensee's work, as well as the work of the contractors and subcontractors performing the work. In turn, the entire range of harvesting activities which a stump to dump contractor has been contracted to administer should be considered that contractor's work in addition to the licensee's work. In this way, the work of a single hand faller, for example, may be considered the work of many entities up the contracting chain for the purposes of establishing the health and safety duties of that entity under section 21(1)(a)(ii).

Every contractor and subcontractor will have health and safety duties with respect to the worker and workplace where the work is carried out. The extent of that duty, and the manner in which it is discharged, will depend on the circumstances. Factors to be considered in assessing whether an employer has a health and safety obligation at a particular workplace include the following:

- The degree of control exercised by the contracting employer over the contractor in other areas of its business. The degree of control should be evaluated by reviewing both the terms of the contract between the parties as well as the reality of the relationship.

- The extent to which the contracting employer knew or should have known of a hazard or situation of non-compliance created by the activities of its contractor. For example, where the contracting employer appoints an individual such as a contract supervisor to monitor compliance with the terms of contract, it may be reasonable to conclude that the contracting employer knew or should have known of a lack of compliance with health and safety requirements.

- Whether it is reasonable to expect the contracting employer to have undertaken safety precautions.

The extent to which an employer took into consideration occupational health and safety matters in structuring and administering its relationship with any contractor it engaged should also be examined.

In engaging a contractor to carry out forestry operations, the contracting employer must take reasonable steps to ensure that the contractor is capable of discharging its health and safety obligations towards its workers and subcontractors, and take reasonable steps to monitor the contractor's safety performance and address any issues that arise. The monitoring activities that are reasonable in the circumstances, ranging from receiving safety reports or reviewing administrative records through to direct inspections, will correlate generally to the degree of control the contracting employer exercises over, and the monitoring of, other aspects of the contractor's operations.

G26.2-2 Planning log hauling operations for varying road grades

Issued: September 28, 2005; Editorial Revision May 1, 2008

Regulatory excerpt

Section 26.2 of the OHS Regulation ("Regulation") states:

(1) The owner of a forestry operation must ensure that all activities of the forestry operation are both planned and conducted in a manner consistent with this Regulation and with safe work practices acceptable to the Board.

(2) Every person who has knowledge and control of any particular activity in a forestry operation must ensure that the activity is both planned and conducted in a manner consistent with this Regulation and with safe work practices acceptable to the Board.

(3) The planning required under this section must

(a) include identification of any work activities or conditions at the workplace where there is a known or reasonably foreseeable risk to workers,

(b) be completed before work commences on the relevant activity, and

(c) be documented at the time of planning.

(4) If, after any planning referred to in subsection (3), there is a change in the workplace circumstances, including the work activities and the conditions of the workplace, and the change poses or creates a known or reasonably foreseeable risk to workers that was not previously identified, then

(a) the plan must be amended to identify and address the risk and provide for the health and safety of the workers at the workplace, and

(b) the amendment must be documented as soon as is practicable.

Purpose of guideline

The purpose of this guideline is to provide direction about appropriate risk assessments that should be conducted in planning log hauling operations on varying road grades to ensure worker safety.

Risk assessment

If log haul operations are to be conducted on road grades that exceed those listed in the Ministry of Forests' Forest Road Engineering Guidebook, a risk assessment should be conducted before any hauling is conducted. The risk assessment factors will depend on the grade of the road, namely

- Grades 0 to 18% (18% for short pitches is the maximum listed in the Forest Road Engineering Guidebook)

The following conditions should be in place to ensure log haul operations on these grades do not present a safety concern:

- The vehicle can be brought to a safe stop on the road surface and grade given the weather conditions at that time.

- The vehicles are properly maintained.

- Speed is not excessive (excessive speed for this guideline is considered as speed above the design speed, above which the operator is not in adequate control of the vehicle, or speed above which the unit could not be brought to a safe stop given a single failure in the driveline).

- Vehicle loads are within the limits of the equipment.

- Grades in excess of 18% (grades exceeding road grades listed in the Ministry of Forests' Forest Road Engineering Guidebook):

There are many factors that contribute to safe operations on these grades, including: weather conditions; road surface friction; grade and horizontal alignment; side slope; velocity of the vehicle; load carried by the vehicles; size, style and condition of brakes; obstacles ahead; and location and size of drop-offs.

The employer must perform a risk assessment to ensure that the equipment being used is capable of performing in a safe manner given weather conditions at the time of log hauling. This assessment should include the following:

- Specifications regarding the road surface condition;

- Vehicle speed

- Length of pitch

- Road relief

- Curve radius

- Comments on specific terrain hazards to negotiate

The risk assessment should not rely solely on the fact that trucks or other equipment may have negotiated similar roads without incident during past operations.

The risk assessment should also address the situation where if an upset condition (such as adverse weather conditions or a failure in the driveline) were to occur, how that upset condition would be controlled or mitigated. The risk assessment needs to confirm that the vehicle or other equipment can be brought to a safe stop under the anticipated hauling or upset conditions. If hauling conditions fall outside the anticipated parameters of the risk assessment, a reassessment should be conducted before hauling continues.

A clear work procedure must be developed based upon the risk assessment described above and include specific instructions for all factors included in the risk assessment. In addition, the risk assessment should include instructions for correct brake adjustment, and if necessary, brake temperature checks. The risk assessment and subsequent work procedure should be discussed and agreed upon with the loading and hauling crews.

Once completed, the risk assessment must confirm that the vehicles or other equipment travelling on these slopes are capable of doing so safely before hauling operations begin.

G26.2-3 Multiple cuts - Mechanical falling

Issued February 19, 2016; Editorial Revision July 3, 2018

Regulatory excerpt

Section 26.2 of the OHS Regulation ("Regulation") states:

(1) The owner of a forestry operation must ensure that all activities of the forestry operation are both planned and conducted in a manner consistent with this Regulation and with safe work practices acceptable to the Board.

(2) Every person who has knowledge and control of any particular activity in a forestry operation must ensure that the activity is both planned and conducted in a manner consistent with this Regulation and with safe work practices acceptable to the Board.

(3) The planning required under this section must

(a) include identification of any work activities or conditions at the workplace where there is a known or reasonably foreseeable risk to workers,

(b) be completed before work commences on the relevant activity, and

(c) be documented at the time of planning.

(4) If, after any planning referred to in subsection (3), there is a change in the workplace circumstances, including the work activities and the conditions of the workplace, and the change poses or creates a known or reasonably foreseeable risk to workers that was not previously identified, then

(a) the plan must be amended to identify and address the risk and provide for the health and safety of the workers at the workplace, and

(b) the amendment must be documented as soon as is practicable.

Purpose of guideline

This guideline is intended to provide information on using mechanical harvesters to fall trees using multiple cuts and the planning that is required before such cuts are made. The guideline should be read in conjunction with G26.2-1 Planning and conducting a forestry operation and G26.16 Slope limitations - Safe work procedures.

Scope of guideline

This guideline only applies to using multiple cuts to completely fall a tree before proceeding to fall the next tree. Using multiple cuts to fall a single tree before proceeding to fall the next tree is acceptable where the process is adequately planned and safe work practices are developed, implemented, and followed.

This guideline does not apply to partially cut trees which are either bypassed or left unattended during the falling process, as outlined in section 26.29.3 of the Regulation. There are currently no safe work practices acceptable to WorkSafeBC under section 26.29.3(3) permitting what is commonly known as "double-pass cutting" or "double-cutting", in which a mechanical harvester works along the front of a row of trees, partially cutting each tree in sequence (leaving each partially-cut tree unattended), and then works its way along the back of the row to complete the cuts and guide the trees to the ground. "Double-pass cutting" does not take into account tree condition or machine capacity, nor does it consider the limited ability of the harvester operator to accurately determine how much of the base diameter of the tree has been cut off or how much holding wood is left to support the standing tree.

Planning

Section 26.2(2) of the Regulation requires that every person who has knowledge and control of any particular activity in a forestry operation must ensure that the activity is both planned and conducted in a manner consistent with the Regulation and with safe work practices acceptable to WorkSafeBC.

Adequate planning should include the selection of equipment capable of safely falling the size and condition of trees on the block. Employers and others should be mindful of the requirements of section 4.3(1) of the Regulation which states:

The employer must ensure that each tool, machine and piece of equipment in the workplace is

(a) capable of safely performing the functions for which it is used, and

(b) selected, used and operated in accordance with

(i) the manufacturer's instructions, if available,

(ii) safe work practices, and

(iii) the requirements of this Regulation;

section 26.12.1 of the Regulation which states:

(1) Any equipment designed for a specific function in a forestry operation or adapted for use in a forestry operation must be capable of performing safely the functions for which it is being used.

(2) The requirements of subsection (1) are met if the equipment is used

(a) in accordance with the manufacturer's instructions,

(b) as specified by a professional engineer, or

(c) in a manner acceptable to the Board;

and section 26.29.2 of the Regulation which states:

A mechanical harvester must not be used to fell a tree if

(a) the tree is in a condition that, if felled in that condition, it would pose a reasonably foreseeable risk to the harvester operator, or

(b) the mechanical harvester is not capable of falling the tree safely.

In addition, adequate planning should address the particular hazards and risks present on the block. These items are listed below under the headings of "site-specific procedures."

Safe work practices

The following safety considerations should be taken into account when falling trees with mechanical harvesters using multiple cuts:

- Multiple cuts should only be used to directionally fall a tree

- The equipment must have sufficient pushing power to direct the tree against its lean

- Sufficient holding wood should be maintained until the machine is positioned to make the final cut

Safe work practices for conducting multiple falling cuts should include both general and site-specific procedures.

General procedures should address the following issues:

- How the harvester operators will be trained and instructed in the work to be performed

- How the work is to be supervised and monitored

- How the harvester operator will maneuver the machine in order to complete the falling process

- The steps the operator will take when cutting any trees to gain access to the full 360 degrees of the initial tree being cut. If full access is not possible without falling other trees first, the harvester operator must first fall those trees that are preventing access before any cuts are made in the initial tree

- Steps to follow in the event falling cuts are initiated and cannot be completed

- An assessment by the harvester operator of the hazards associated with multiple falling cuts, such as stability of the tree (top and stem, excessive rot, limb tied, etc.)

- Maintaining directional control over the tree by the harvester operator through the falling process

- Control of the fall of the tree by the harvester operator in a manner that ensures the stability of the machine and the protection of the operator at all times

- The steps that will be taken to ensure the health and safety of all workers who may be exposed to the hazard of the tree during the multiple cutting process

Site-specific procedures should address the particular hazards and risks present at the time and place the falling takes place, such as the following:

- Topography (slope, broken rock, loose shale, stable, or slippery snow pack, etc.)

- Wind and weather conditions, including an assessment of visibility and ability to clearly see the tree from ground to top

- Other work activity taking place at the falling location

- The condition of the tree or trees to be partially cut to ensure they are stable enough to support multiple cuts. This assessment should consider the likelihood of the trunk collapsing due to decay or other defect (taking into account and the possibility of the top of the tree breaking off and striking the machine)

- Slope limitations that may affect harvester stability while making cuts or pushing the tree over

- How to effectively control the fall of trees during the falling process to ensure that no additional hazards to workers are created by the actions of the harvester

Hazards to consider and mitigate include the following: - brushing of standing timber

- damage to adjacent trees

- whether falling is upslope

- accumulation of debris against the butt of standing trees if a hand faller or other worker will later be at the base of the tree for other types of work

G26.3.1(1)(a) Acceptable standard for training

Issued February 11, 2009

Regulatory excerpt

Section 26.3.1(1) of the OHS Regulation ("Regulation") states:

(1) Workers in a forestry operation who fight a forest fire must be

(a) trained in their fire fighting duties in accordance with a standard acceptable to the Board, and

(b) physically capable of performing their duties safely and effectively.

Purpose of guideline

The purpose of this guideline is to specify the training requirements for workers in a forestry operation in order for them to be considered trained in accordance with a standard acceptable to WorkSafeBC for section 26.3.1(1)(a) of the Regulation.

Standard acceptable to WorkSafeBC

S-100 Basic Fire Suppression and Safety is a training program developed by the B.C. Forest Service (BCFS), Protection Branch of the Ministry of Forests and Range. Workers who have been trained in S-100 and have received a certificate of completion from a BCFS-endorsed instructor are considered to have been trained in accordance with a standard acceptable to WorkSafeBC.

Alternative training standards

Employers, or training providers, who have developed training standards other than

S-100, may apply to WorkSafeBC for review. Applications can be made to the Manager of the Certification Services department of WorkSafeBC.

G26.11 Wildlife dangerous tree assessment

Issued December 14, 2012; Editorial Revision January 29, 2014; Editorial Revision July 30, 2021

Regulatory excerpt

Section 26.11 of the OHS Regulation ("Regulation") states:

(1) If it is known or reasonably foreseeable that work will expose a worker to a dangerous tree,

(a) the tree must be felled, or

(b) a risk assessment of the tree must be undertaken by a person who has completed a training program acceptable to the Board.

(2) If a risk assessment under subsection (1) determines that a tree poses a risk to a worker, the recommendations made in the risk assessment for eliminating or minimizing the risk must be implemented before the work referred to in that subsection starts.

(3) Despite subsections (1) and (2), if work in a forestry operation is to be carried out in an area that has more than 500 dangerous trees per hectare, the Board may approve a request to work without felling or assessing all the dangerous trees if, before the work starts,

(a) a person who has completed a training program acceptable to the Board conducts a risk assessment of a representative sample of the dangerous trees, and

(b) any recommendations made in the risk assessment for eliminating or minimizing the risks are implemented.

Section 26.1 of the Regulation states:

"dangerous tree" means a tree that is a hazard to a worker due to

(a) its location or lean,

(b) its physical damage,

(c) overhead conditions,

(d) deterioration of its limbs, stem or root system, or

(e) any combination of the conditions in paragraphs (a) to (d);

Purpose of guideline

The purpose of this guideline is to describe an acceptable training program to WorkSafeBC with respect to a person who will be qualified to undertake a dangerous tree risk assessment.

Background

Dangerous trees present significant hazards to those working in proximity to them. It is important that the hazards of dangerous trees are identified and adequately managed. Where work may expose a worker to a dangerous tree, section 26.11 requires a risk assessment to be performed by a person who has completed a training program acceptable to WorkSafeBC, and that person to make recommendations for managing the hazard. The purpose of this guideline is to set out what training program is acceptable to WorkSafeBC.

Training programs acceptable to WorkSafeBC

For the purposes of section 26.11 of the Regulation, currently there are two training programs acceptable to WorkSafeBC, each with a different focus.

In the context of forest harvesting & silviculture, parks & recreation, and wildland fire safety operations, only a person who has completed the Wildlife Dangerous Tree Assessor's Course, administered by the Wildlife Tree Committee (WTC), can complete a risk assessment and make recommendations for managing dangerous trees.

The WTC is a multi-agency committee composed of representatives from the provincial Ministry of Forests and Range, Ministry of Environment and Climate Change, WorkSafeBC, industry, labour, and public interest groups from across the province. The training course provides information and technical procedures for assessing dangerous trees and establishing appropriate safe work practices in situations where there is potential exposure of workers.

With respect to arboriculture operations, the Tree Risk Assessment Qualification (TRAQ) course provides training with respect to the assessment of dangerous trees that exist in urban areas and urban and/or rural interface areas, and is an acceptable training program to WorkSafeBC for dangerous tree assessors in that industry. The TRAQ course is administered by the International Society of Arboriculture (ISA).

Other courses

WorkSafeBC recognizes that other training courses may be developed that may meet the requirements for acceptance under section 26.11(1) of the Regulation. WorkSafeBC will review any proposed courses for acceptance to ensure they meet a standard acceptable to WorkSafeBC. Any new courses WorkSafeBC identifies as acceptable under section 26.11(1) will be added to this guideline for the information of workplace parties and WorkSafeBC prevention officers.

Persons wishing to have WorkSafeBC consider an alternative course for acceptance under section 26.11(1) may submit that course to WorkSafeBC for review and evaluation. Please contact Certification Services for further information.

Guidelines Part 26 - Equipment Operation

G26.16 Slope limitations - Safe work procedures

Issued November 18, 2009; Revised April 13, 2011

Regulatory excerpt

Section 26.16 of the OHS Regulation ("Regulation") states:

(1) Repealed. [B.C. Reg. 312/2003, effective October 29, 2003.]

(2) If the manufacturer's maximum slope operating stability limit for logging equipment is known, the equipment must be operated within that limit.

(3) If the manufacturer's maximum slope operating stability limit for logging equipment is not known, the equipment must be operated within the following limits:

(a) a rubber tired skidder must not be operated on a slope which exceeds 35%;

(b) a crawler tractor, feller buncher, excavator and other similar equipment must not be operated on a slope which exceeds 40%;

(c) any other forestry equipment specifically designed for use on a steep slope must not be operated on a slope which exceeds 50%.

(4) Despite subsections (2) and (3) but subject to subsection (5), logging equipment may be operated beyond the maximum slope operating stability limits specified in those subsections if

(a) a qualified person conducts a risk assessment of that operation, and

(b) written safe work practices acceptable to the Board are developed and implemented to ensure the equipment's stability during operation.

(5) Despite anything in this section, logging equipment must not be operated in a particular location or manner if its stability cannot be assured during that operation.

Purpose of guideline

This guideline is intended to give direction as to what is required for an employer to fulfill the obligations of sections 26.16(4)(a)(b) and 26.16(5) with respect to the development of safe work procedures for the operation of equipment beyond the limitations in section 26.16(3) and to ensure stability of logging equipment on steep slopes.

Operating logging equipment on steep slopes

The operation of logging equipment on steep slopes presents a serious hazard in the form of equipment rollover, which can result in serious injury or death to equipment operators and other workers. It is therefore crucial that logging equipment be operated within the manufacturer's safe operating stability limit. Where that limit is unknown, section 26.16(3) sets out slope limitations for particular pieces of equipment. Despite these restrictions, logging equipment may be operated beyond these slope limitations, provided that there is a risk assessment of the operation done by a qualified person and there are safe work practices acceptable to WorkSafeBC implemented during the operation.

The intention of sections 26.16(4)(a)(b) and 26.16(5) is to permit the employer and owner of the workplace to allow the slope stability limitations to be exceeded in situations in which it may not be viable or practicable to bring in an alternate harvesting system. Operating equipment for longer durations on slopes that are at or beyond the equipment's safe operating limit overburdens machinery. Because this activity increases workers' exposure to risk, these operations have to be carefully managed, planned, and supervised.

Steep slope operations need to involve careful management of both the hazards presented by the terrain and the duration of workers' exposure to the hazard.

In addition, employers and others should be mindful of the requirements of section 26.12.1(1) of the Regulation, which states:

Any equipment designed for a specific function in a forestry operation or adapted for use in a forestry operation must be capable of performing safely the functions for which it is being used.

Section 26.16(5) of the Regulation states:

Despite anything in this section, logging equipment must not be operated in a particular location or manner if its stability cannot be assured during that operation.

The following sets out the required considerations for operating logging equipment on steep slopes beyond the manufacturer's maximum operating stability limit or the limits in section 26.16(3). In order to be compliant with section 26.16(4), such operations must be

- Adequately planned

- Subject to a thorough site-specific risk assessment, with defined steep slope sites identified

- Conducted in accordance with site-specific safe work practices acceptable to WorkSafeBC

Planning for steep slope logging

Section 26.2(1) of the Regulation states:

The owner of a forestry operation must ensure that all activities of the forestry operation are both planned and conducted in a manner consistent with this Regulation and with safe work practices acceptable to the Board.

Forestry operations must be properly planned and conducted in a manner consistent with the Regulation and safe work practices acceptable to WorkSafeBC.

Regulation section 26.2(3)(a) states that this obligation "include identification of any work activities or conditions at the workplace where there is a known or reasonably foreseeable risk to workers."

The planning of forestry operations must include identification of any steep slope areas in a cut block to determine how these areas will be dealt with. If a block that has been selected for harvest has slopes that are outside of the maximum operating stability limits of the machines intended for use at this workplace, then consideration must be given to whether the harvesting plan can be amended to identify a more appropriate selection of equipment or techniques for the workplace, such as specially designed steep slope equipment or a cable system.

Note that under sections 26.2(3)(b) and (c), the planning of a forestry operation must be completed before work commences and documented. Therefore any identification of areas of steep slope logging and the plan regarding how to deal with those areas, including the risk assessment and the work procedures, must be carried out and documented before the work is undertaken.

Conducting the risk assessment

Once a cut block has been assessed and defined portions of the cut block have been identified as having slopes that will exceed the operating stability guidelines of the logging equipment, the first obligation of the employer prior to exceeding these slope limits is to have a qualified person conduct a risk assessment. Based upon this risk assessment, appropriate site-specific safe work procedures are to be developed that will assure machine stability on the slopes.

The required elements of the risk assessment are to

- Identify and assess the steep slopes in the cut block

- Evaluate the duration of worker exposure to work in steep slope areas

- Evaluate risks posed by the characteristics of the terrain, including the following:

- the degree of slope

- terrain classification, and the soil conditions that can be expected, including depth of soils and underlying materials

- ground roughness including rocky areas, loose soils, or materials

- the impact of operations on the hydrology of the site, and any resulting effects on terrain stability

- Evaluate machine capabilities, limitations, and performance characteristics

- Consider operational factors such as

- average tree size

- approximate tree weights and species

- allowable stump height

- any harvesting site-specific specifications

- Consider environmental considerations such as weather (i.e., rain, wind, snow, frost, fog)

- Consider how isolated the work will be and the proximity to assistance

- Determine any other relevant risk factors present at that workplace

In accordance with section 26.2(3)(c) of the Regulation the risk assessment must be adequately documented at the time of planning.

The risk assessment must be carried out by a "qualified person." The Regulation defines qualified as follows:

"qualified" means being knowledgeable of the work, the hazards involved and the means to control the hazards, by reason of education, training, experience or a combination thereof

The "qualified person" for the purposes of section 26.16 must be capable of competently evaluating the elements of the risk assessment listed above. The person conducting the risk assessment for steep slope operations is expected to

- Possess extensive experience in working on steep slopes in variable terrain and conditions

- Be knowledgeable of the machines being used during the total harvesting operation; not just one phase such as bunching. The familiarity with the equipment must include the selection of the equipment, limitations on maneuverability and stability, and use of accessories which would increase traction or stability (e.g., chains or grousers)

- Be familiar with the training needs and experience of the logging equipment operators

- Be familiar with the specific site to be harvested which would include knowledge of the terrain, soils, and weather variables for the location including the planned season of harvest

- Be knowledgeable in developing safe work procedures that are based upon a site-specific risk assessment

Ideally the qualified person will possess formal training or trade certification (such as a Registered Professional Forester) that would suggest the person is capable of exercising responsible and sound judgment. Given that in order to complete the risk assessment there must be an overall understanding of the entirety of the steep slope logging operations, the qualified person should typically be someone other than the equipment operator, unless that operator is in a supervisory capacity and possesses the skills and knowledge outlined above.

Where the qualified person does not possess the knowledge or information outlined above, this individual needs to be capable of obtaining the information from others, and be capable of fully understanding the information and incorporating it into the assessment.

Developing and implementing safe work practices

In order to operate equipment in areas which exceed manufacturer's safe operating limits or the limits in section 26.16(3), safe work practices acceptable to WorkSafeBC must be developed and adequately documented.

The following elements are those that WorkSafeBC considers necessary for the safe work practices to be acceptable. In conducting inspections or investigations, WorkSafeBC prevention officers will compare the employer's safe work practices to ensure they meet the elements listed below.

a) Link to risk assessment

The site-specific machine stability steep slope safe work practices are to be created with specific reference to the conditions identified and evaluated in the risk assessment.

b) Identification of the work area

Where possible, the safe work practices should address minimizing the extent of the steep slope work and ensuring that the duration of worker exposure to steep slope areas is kept manageable.

This should also include, where possible, the identification of "no go" areas, including any cutoff points in the cut block that are designated as too steep, rocky, or unstable and are no go zones for the equipment being used.

Other considerations may include machine free zones or setback distances from environmentally sensitive areas, and areas that are prone to sliding or washout.

c) Equipment selection and operating procedures

Safe work practices are to cover equipment selection and set out which machine is most appropriate for use on the slope being harvested based upon a stability assessment of the machine. This stability assessment should consider things such as

- Manufacturer's specifications

- Consideration of features intended to facilitate equipment performance on steep slopes, such as self leveling cabs

- Safety equipment on the machine including Roll Over Protective Structures (ROPS) and seatbelts

- Visibility for operators

- Condition of the tires including inflation

- Use and condition of chains and band tracks, and on tracked equipment the condition of the tracks, grousers, and guarding

Note that equipment maintenance will be critical for machines used on steep slopes as break downs in these areas will compound the risk to the machine operators.

Safe work practices will have to address equipment selection even where equipment designed for steep slope situations is being used. However, the risk assessment and resulting safe work practices may be streamlined in such situations.

Specific procedures should address the following:

i. Planning the direction of equipment travel for each piece of equipment used in the harvesting operation. This is to be considered with a view to keeping the logging equipment on the lowest gradient of slope during the work as well as providing the greatest stability for the equipment. Always avoid cross slope travel and winching a turn of logs at an angle to the machine. Always travel down slope keeping the logs tight to the apron and close to the machine.

ii. Addressing the effects upon weight distribution and changes to the centre of gravity on the machine when negotiating the slope and any ground variations.

iii. When operating a feller buncher, considering the width of the falling swath, as the slope increases in steepness usually the width of the swath will decrease. With an increase in the gradient of the slope the feller buncher will limit the slewing width which allows the operator to keep the felling machine's centre of gravity close to the face of the slope which increases machine stability.

iv. Addressing how to effectively handle loads, for example, weight transfer when rotating larger trees on a steep slope which can be dealt with by drawing the tree towards the machine or felling at a 45 degree angle to the slope, or ensuring that loads on forwarders are moderate size and do not over balance the machine.

d) Address undertaking site modifications where appropriate

Procedures need to identify areas in which modifications to the site are acceptable and planned to increase machine stability. This could include the construction of skid trails or roads as appropriate.

e) Operator qualifications, training, and supervision

The safe work practices need to set out how the equipment operators will be trained and instructed on how the work is to be performed. In addition, they must set out how the work is to be supervised and monitored.

f) Dealing with emergencies

Procedures need to be in place for dealing with equipment breakdown, situations where equipment operators find themselves in difficulties, and for dealing with an upset condition. Equipment will have to be available to render assistance in such situations.

Implementing safe work practices

Safe work practices encompassing these elements must not only be developed, they must be implemented. Employers must ensure that these procedures not only exist, but that equipment operators and other workers involved in the operation are provided instruction and training in the procedures. Section 26.3 of the Regulation requires all workers to have received training necessary to perform their duties. Though this training need not be overly formal, it needs to be adequately documented.

In addition, employers must ensure that these procedures are followed by these workers. This would involve adequate supervision and monitoring of the operations by qualified people and correcting any deviation from the procedures, as well as identifying any new risks that arise during the operations and adjusting the safe work practices accordingly.

G26.18 Acceptable standards for landslide risk assessments

Issued December 18, 2015; Editorial Revision November 21, 2017; Editorial Revision consequential to August 22, 2022 Regulatory Amendment

Regulatory excerpt

Section 1.1 of the OHS Regulation ("Regulation") states:

"qualified registered professional" means

(a) a professional engineer or professional geoscientist, and

(b) in relation to a forestry operation, a person referred to in paragraph (a) or a person registered under the Professional Governance Act as

(i) a professional forester, or

(ii) a registered forest technologist;

Section 26.18 of the Regulation states:

In a forestry operation where there may be a risk of a landslide

(a) the risk must be assessed in accordance with a standard acceptable to the Board,

(b) if a risk is found to be present, written safe work procedures must be developed meeting the requirements of the standard, and

(c) workers must be educated in the safe work procedures.

Purpose of guideline

The purpose of this guideline is to identify the acceptable standard for performing landslide risk assessments and developing written safe work procedures under section 26.18 of the Regulation. The guideline also clarifies that this work must be done by a

qualified registered professional, with appropriate qualifications in landslide risk assessments.

Landslide risk assessments as professional work

Section 26.18 requires that landslide risks are assessed, and that safe work procedures

are developed to address those risks. While section 26.18 does not specify who may

perform this work, the work falls within the professional practices regulated under the

Professional Governance Act. This Act prohibits individuals

other than qualified registered professionals from performing this work.

The respective professional associations may place additional qualification requirements on their members to be able to perform landslide risk assessments. Where a WorkSafeBC prevention officer identifies that an individual is performing landslide risk assessments without being a qualified registered professional, or is otherwise unqualified, the prevention officer will refer that matter to the appropriate professional association. The prevention officer may also write orders under section 26.18.

Acceptable standards for landslide risk assessments and safe work procedures

Engineers & Geoscientists British Columbia (EGBC) and the Association of British Columbia Forest Professionals have developed the following

three guidelines concerning landslides:

- Guidelines for Managing Terrain Stability in the Forest Sector

- Guidelines for Professional Services in the Forest Sector – Terrain Stability Assessments

- Guidelines for Professional Services in the Forest Sector – Forest Roads

The Guidelines for Managing Terrain Stability in the Forest Sector may be used to determine whether or not there is a risk of a landslide. Where a risk of a landslide is present, section 26.18 of the Regulation applies and the Guidelines for Professional Services in the Forest Sector – Terrain Stability Assessments (TSA Guideline) is an acceptable standard for performing the work under section 26.18.

The Guidelines for Professional Services in the Forest Sector – Forest Roads may be of additional assistance for employers applying the TSA Guideline where the risk of a landslide is connected to road building activities.

Landslide risks assessments, where necessary, should be incorporated into how a forestry operation is planned and conducted in accordance with section 26.2 of the Regulation.

Guidelines Part 26 - Manual Falling and Bucking

G26.21/26.22 Faller training – Application

Issued September 28, 2005; Revised May 1, 2008; Editorial Revision April 14, 2009; Editorial Revision May 9, 2014; Editorial Revision April 30, 2015; Editorial Revision October 28, 2015; Editorial Revision November 21, 2017; Editorial Revision May 31, 2021

Regulatory excerpt

Sections 26.21 and 26.22 of the OHS Regulation ("Regulation") state, in part:

26.21 Faller qualifications

(1) A worker must not fall trees or be permitted to fall trees, or conduct or be permitted to conduct bucking activities, associated with falling trees, unless

(a) the worker is qualified to do so to a standard acceptable to the Board, and

(b) the work being performed is within the documented and demonstrated capabilities of that worker.

…

26.22 Forestry operation faller training

(1) A worker may not work as a faller in a forestry operation unless the worker receives training for falling that is acceptable to the Board and is certified in writing as a competent faller under this section.

…

Purpose of guideline

Hand falling remains one of the most dangerous professions in British Columbia. It is crucial that fallers are trained in safe work practices so that they are able to recognize and eliminate or minimize hazards.

The purpose of this guideline is to outline what training is acceptable to WorkSafeBC for the purposes of section 26.22(1) of the Regulation, and who is required to receive faller training. It also describes what the "documented and demonstrated capabilities" of the worker mean for the purposes of section 26.21 of the Regulation.

Who must receive training?

The faller training requirement in section 26.22 of the Regulation applies to workers in a "forestry operation." Section 26.1 of the Regulation states that a forestry operation "means a workplace where work is done in relation to silviculture or harvesting trees, including constructing the means of access and transporting the harvested trees to a facility where they are processed or from which they are exported." Workers who fall trees in such workplaces will have to be trained and certified in accordance with section 26.22 of the Regulation. For discussion of what "forestry operation" is intended to cover, refer to OHS Guideline G26.1-1 Forestry operations and similar activities.

Faller training

To address the need for acceptable training, WorkSafeBC, in conjunction with forest industry employer associations, representatives of organized labour, and experienced hand fallers, has developed a faller training standard that meets the requirements of section 26.22 of the Regulation.

The delivery of training and certification meeting the BC Faller Training Standard (BCFTS) is administered by the following organizations:

- BC Forest Safety Council (BCFSC)

- Canadian Association of Geophysical Contractors (CAGC)

- BC Wildfire Service (Ministry of Forests, Lands, Natural Resource Operations and Rural Development)

For more information about faller training and certification and for the contact information of the BCFTS administrators, refer to the Faller certification webpage.

The BCFTS consists of two primary components. The first component addresses new faller training, and covers the selection and use of appropriate personal protective equipment, the maintenance and operation of falling equipment, and tools, hazard recognition and control, and safe falling, bucking, and limbing procedures. The second component involves a written exam and a practical field evaluation of the faller's falling abilities, which, if successfully completed, will result in the issuance of a certificate to the faller.

Other courses

WorkSafeBC recognizes that other training courses may be developed that may meet the requirements for acceptance under section 26.22(1) of the Regulation. WorkSafeBC will review any proposed courses for acceptance to ensure consistency with the BCFTS. Any new courses WorkSafeBC identifies as acceptable under section 26.22(1) of the Regulation will be added to this guideline for the information of workplace parties and WorkSafeBC prevention officers.

Persons wishing to have WorkSafeBC consider an alternative course for acceptance under section 26.22(1) of the Regulation may submit that course to WorkSafeBC for review and evaluation. Contact Certification Services for further information.

Forestry operation fallers – Employer's obligation to ensure faller qualified

While the obligations in section 26.22 regarding receiving training are imposed on workers in a forestry operation, employers should note their obligations under section 26.21 of the Regulation.

Employers are required, as part of the obligation in section 26.21, to verify that fallers have received WorkSafeBC approved training. This can be done by ensuring that the faller possesses a valid faller training certificate or by enquiring with the BCFSC.