Contents

G34.1 Definitions – Boatswain's (Bosun's) chair

G34.4(1)(a) Training and certification

G34.4(1)(b) Certification for Climbing Gym Instructors

G34.5 Safe work practices

G34.6(3) Two-rope system – Independent connections

G34.8 Rescue – Prompt rescue

G34.9 Equipment – Standards

G34.12 Permanent anchors – Inspection and testing

Guidelines Part 34 - Rope Access

G34.1 Definitions – Boatswain's (Bosun's) chair

Issued consequential to February 1, 2015 Regulatory Amendment

Regulatory excerpt

Section 34.1 of the OHS Regulation ("Regulation") states, in part:

"rope access system" means a system consisting of

(a) a sit harness or full body harness,

(b) rope, lanyards and other connecting equipment,

(c) anchors, and

(d) other components such as ascenders, descenders, belay devices, backup devices and fall arresters,

that usually employs 2 separately secured subsystems, one as a means of access and the other as a safety, secondary, belay or backup system, but does not include a boatswain's chair, also known as a bosun's chair, or a zipline;

Purpose of guideline

The regulatory requirements in Part 34 for a rope access system do not apply to a bosun's chair. This guideline provides information to help distinguish between rope access comfort work seats used in rope access systems and bosun's chairs.

Boatswain's (bosun's) chairs and comfort work seats

A bosun's chair is a single-person worker support system, generally composed of the following:

- A seat

- Ropes or webbing which support the seat

- D-ring(s) at the ends of the ropes or webbing (refer to Figure 1)

Under the Regulation, it is considered as a work platform, and is defined in Part 13 as "a seat attached to a suspended rope designed to accommodate one person in a sitting position." The ropes or webbing typically terminate at the worker's chest level. In order to prevent the worker from falling from the seat, a body support strap or straps may be incorporated into the design. The D-ring(s) may be attached to a means of ascent and/or descent, (e.g., a winch or a block-and tackle system). The means of ascent/descent is also connected to the working line.

A bosun's chair supports the worker, and is the worker's connection to the means of ascent and/or descent and the working line. The bosun's chair is therefore integral to the work positioning system. If the worker were to lose contact with the bosun's chair, the worker's connection to the means of ascent and/or descent would be compromised, as would the worker's connection to the working line.

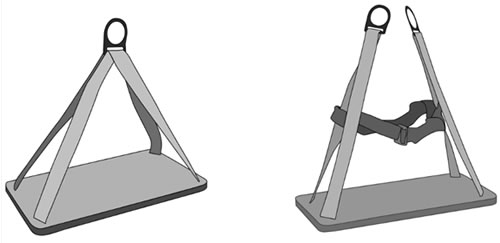

Figure 1 Bosun's chair

Although similar in appearance to a bosun's chair, a comfort work seat (refer to an example in Figure 2) used in rope access is fundamentally different. The only point of connection for the comfort work seat is the worker's harness. It is not connected to the means of ascent/descent or to the working line. In contrast, a bosun's chair is integral to a work positioning system. A comfort work seat is an accessory to a rope access system. Therefore, the worker could remove the comfort work seat without affecting the connection to the working line.

Figure 2 Rope access comfort work seat

G34.4(1)(a) Training and certification

Issued consequential to February 1, 2015 Regulatory Amendment; Revised July 22, 2020

Regulatory excerpt

Section 34.4(1)(a) of the OHS Regulation ("Regulation") states:

(1) Before allowing a person to perform rope access, the employer must ensure and document that the person

(a) has received training in the safe use of a rope access system, including, as appropriate to the work being done, the safe work practices, skills and practical experience hours described in one of the following groups of publications:

(i) International Code of Practice (2013) and General requirements for certification of personnel engaged in industrial rope access methods, Edition 6 (June 2009), published by the International Rope Access Trade Association;

(ii) Safe Practices for Rope Access Work (August 2012) and Certification Requirements for Rope Access Work (November 2012), published by the Society of Professional Rope Access Technicians;

(iii) Scope of Practice (2012), Technical Handbook for Professional Mountain Guides (1999) and Climbing Gym Instructor Technical Manual (2003), published by the Association of Canadian Mountain Guides;

(iv) Cave Guiding Standards for British Columbia and Alberta (January 2004), published by the Canadian Cave Conservancy, and Companion Rescue Workshop (2011), published by British Columbia Cave Rescue

Purpose of guideline

This guideline clarifies how rope access training relates to different disciplines of work. It also accepts an alternative code for certification of rope access technicians.

Rope access training and certification

Part 34 applies to activities in industrial operations, professional mountain guides, climbing gym instructors, and cave guides. Although these disciplines are all addressed in Part 34, they are not equivalent when it comes to required worker training and use of safe work practices.

The techniques and practices required for each discipline are different and are not interchangeable between disciplines. Training and certification in one discipline does not apply to work being done in another discipline. For example, training as a cave guide is not appropriate for industrial rope access work (e.g., building maintenance or bridge inspection), and certification as a climbing gym instructor is not appropriate for mountain guiding.

Rope access certification – alternative codes

Section 34.4(1)(a)(i) of the Regulation – WorkSafeBC has determined that the Industrial Rope Access Trade Association ("IRATA") Training, Assessment and Certification Scheme ("TACS") for personnel engaged in industrial rope access methods (August 2014) is an acceptable alternative to the IRATA General requirements for certification of personnel engaged in industrial rope access methods, Edition 6 (June 2009).

Section 34.4(1)(a)(ii) of the Regulation – WorkSafeBC has determined that the Society of Professional Rope Access Technicians (SPRAT) Safe Practices for Rope Access Work (September 2019 and May 2020) and Certification Requirements for Rope Access Work (November 2019 and May 2020) are acceptable alternatives to the Safe Practices for Rope Access Work (August 2012) and Certification Requirements for Rope Access Work (November 2012).

G34.4(1)(b) Certification for Climbing Gym Instructors

Issued April 30, 2015; Revised July 15, 2019

Regulatory excerpt

Section 34.4(1) of the OHS Regulation ("Regulation") states:

(1) Before allowing a person to perform rope access, the employer must ensure and document that the person

(a) has received training in the safe use of a rope access system, including, as appropriate to the work being done, the safe work practices, skills and practical experience hours described in one of the following groups of publications:

(i) International Code of Practice (2013) and General requirements for certification of personnel engaged in industrial rope access methods, Edition 6 (June 2009), published by the International Rope Access Trade Association;

(ii) Safe Practices for Rope Access Work (August 2012) and Certification Requirements for Rope Access Work (November 2012), published by the Society of Professional Rope Access Technicians;

(iii) Scope of Practice (2012), Technical Handbook for Professional Mountain Guides (1999) and Climbing Gym Instructor Technical Manual (2003), published by the Association of Canadian Mountain Guides;

(iv) Cave Guiding Standards for British Columbia and Alberta (January 2004), published by the Canadian Cave Conservancy, and Companion Rescue Workshop (2011), published by British Columbia Cave Rescue, and

(b) holds a valid certificate of the training referred to in paragraph (a) issued by a body or association referred to in subparagraphs (i) to (iv) of that paragraph.

Section 4.4(2) of the Regulation states:

(2) When this Regulation requires a person to comply with

(a) a publication, code or standard of the Board or another agency, the person may, as an alternative, comply with another publication, code or standard acceptable to the Board...

Purpose of guideline

The purpose of this guideline is to identify an alternate publication that is acceptable for the training and certification of climbing gym instructors.

Section 34.4(1)(b) of the Regulation requires that rope access workers working as climbing gym instructors hold a valid certificate issued by the Association of Canadian Mountain Guides (ACMG). ACMG is the professional body which issues certification to qualified mountaineers and climbing gym instructors. To comply with section 34.4(1)(b) of the Regulation, workers conducting rope access work described in the Technical Handbook for Professional Mountain Guides (1999) and Climbing Gym Instructor Technical Manual (2003) must possess ACMG certification.

Alternate publication and certification

The training and certification provided by the Climbing Wall Association, Inc. (CWA) "Climbing Wall Instructor Certification Program" for indoor climbing gym instructors is an acceptable alternative to meet the requirements of section 34.4(1)(a)(iii) of the Regulation.

G34.5 Safe work practices

Issued consequential to February 1, 2015 Regulatory Amendment

Regulatory excerpt

Section 34.5 of the OHS Regulation ("Regulation") states:

A person performing rope access must comply with, as appropriate to the work being done, the safe work practices described in one of the groups of publications set out in section 34.4(1)(a)(i) to (iv).

Purpose of guideline

This guideline clarifies how safe work practices relate to different types of rope access work.

Safe work practices

Part 34 applies to industrial rope access (e.g., construction, building maintenance, bridge inspection, rope work at dams), professional mountain guiding, climbing gym instruction, and cave guiding activities, and training in these disciplines. Although these disciplines are all addressed in Part 34, the work practices for the disciplines are not interchangeable. Safe work practices in one discipline do not apply to work being done in another discipline. These practices are usually an integrated set of requirements and recommendations which rely on this integration to provide the necessary level of safety. Use of the integrated set of safe work practices is mandatory under the Regulation.

In addition, safe work practices prescribed by different societies or associations dedicated to the same discipline are not interchangeable. For example, a technician certified by the Industrial Rope Access Trade Association ("IRATA") or the Society of Professional Rope Access Technicians ("SPRAT") must abide by the practices prescribed by that organization. Under the Regulation, the technician certified by one rope access professional body may not instead follow the practices prescribed by the other rope access professional body, or practices specified for a different discipline. This does not prevent a SPRAT technician from using techniques and practices from the IRATA International Code of Practice for Industrial Rope Access (2013) (or vice versa) where doing so does not cause a conflict and is still consistent with the intent of the SPRAT Safe Practices for Rope Access Work document.

Note that section 2.3 of the Regulation specifies that regulatory requirements take precedence over the safe work practices of a certifying organization. For example, required minimum load capacities for permanent and temporary anchors are specified in the Regulation and these requirements supersede any minimum load capacities specified in safe work practice documents of the certifying organizations.

G34.6(3) Two-rope system – Independent connections

Issued consequential to February 1, 2015 Regulatory Amendment

Regulatory excerpt

Section 34.6(3) of the OHS Regulation ("Regulation") states:

(3) In a two-rope system, the working line and the safety, secondary, belay or backup line must

(a) have independent connection points to the system's anchor or anchorage, and

(b) be independently connected to the harness of the person performing rope access.

Purpose of guideline

This guideline clarifies what constitutes an appropriate connection to an anchorage for the two-rope system.

The two-rope system

A key concept in industrial rope access is the use of two separately secured subsystems. Subject to sections 34.6(2) and 34.6(4) of the Regulation, at no point may the failure of any single component in either subsystem result in a failure of the overall system. The system needs to provide redundancy. For example, if the rope access technician's working line were to fail at the point of anchor, the worker must be protected by a properly connected and anchored fall-arrest device on a safety line. Two anchors need to be used, one for each subsystem.

Subject to the requirements of the Regulation, purpose-built, multi-point anchors may be used in accordance with the manufacturer's instructions. Multiple anchors may be used with a single anchorage if the anchorage is reliable and capable of safely withstanding any forces the rope access system may apply to it.

G34.8 Rescue – Prompt rescue

Issued consequential to February 1, 2015 Regulatory Amendment

Regulatory excerpt

Section 34.8 of the OHS Regulation ("Regulation") states:

The employer must ensure that a person performing rope access can be promptly rescued, in accordance with the procedures described in the rope access plan referred to in section 34.3(1), in the event of an equipment malfunction, fall or injury or the person's incapacity to self-rescue.

Purpose of guideline

This guideline clarifies requirements for the prompt rescue of workers after a rope access incident.

Prompt rescue

Prompt rescue includes immediate activation of the rescue plan following equipment malfunction, fall or injury, or a person's inability to self-rescue. A worker may be unable to self-rescue due to a medical event or other factors. In order to provide prompt rescue, the employer should ensure the following prior to the commencement of rope access work:

- The rope access plan includes rescue procedures specific to the work situation

- All workers are trained and able to provide self-rescue

- The rope access team members have sufficient training to competently perform partner rescue and retrieval

- The supervisor is capable of managing a rescue event

- The appropriate equipment is available to provide rescue

- Rescue plans are practiced by team members at regular intervals

- Provision of first aid services

Suspension intolerance

Annex G of the Industrial Rope Access Trade Association ("IRATA") International Code of Practice for Industrial Rope Access (2013) states that suspension intolerance is a condition in which a suspended person, e.g., in a harness, can experience certain symptoms related to restricted blood flow, which can lead to unconsciousness and eventually death. The reason for this is that the body is not tolerant of being in an upright position and motionless at the same time. Persons most likely to be affected are those who are suspended in a generally upright position and who are motionless, for example, when seriously injured or unconscious, or when fastened vertically in a stretcher.

Suspension intolerance is also known by the following names:

- Suspension trauma

- Harness hang syndrome

- Harness-induced pathology

- Suspension pathology

- Suspension syncope

- Orthostatic intolerance

Workers who are suspended vertically in a safety harness and undergo limited motion are at risk of developing suspension intolerance. Safety harnesses, when engaged, place direct pressure on both the femoral artery and femoral vein. Studies show people suspended in a safety harness and motionless can develop signs and symptoms of suspension intolerance within minutes.

G34.9 Equipment – Standards

Issued consequential to February 1, 2015 Regulatory Amendment

Regulatory excerpt

Section 34.9 of the OHS Regulation ("Regulation") states:

(1) Equipment used for a rope access system must

(a) consist of components that are compatible and suitable for the intended use, and

(b) be suitable for the environment in which the equipment is used.

(2) Unless otherwise provided for under section 34.12(1) or 34.13(2), equipment of a type set out in Column 1 of Schedule 34-A must meet the requirements of, and be used in accordance with, one of the applicable standards set out opposite that type of equipment in Column 2.

Purpose of guideline

The purpose of this guideline is to clarify how the standards listed in Schedule 34-A apply to work involving rope access.

Equipment standards

Part 34 applies to equipment used by rope access technicians, professional mountain guides, climbing gym instructors, and cave guides. Equipment standards for the disciplines are not interchangeable. For example, although a connector may be certified to a mountaineering and climbing equipment standard, it is not appropriate for use in an industrial setting (e.g., construction or building maintenance), unless it is also certified to an applicable industrial rope access or fall arrest standard.

There may be instances where a person finds it impracticable to comply with the equipment standards referenced in Schedule 34-A, and wishes to use equipment that meets a different recognized standard. In this case, application should be made to WorkSafeBC's Prevention Practice, Quality, and Engineering department for acceptance of the alternative standard.

G34.12 Permanent anchors – Inspection and testing

Issued consequential to February 1, 2015 Regulatory Amendment

Regulatory excerpt

Section 34.12 of the OHS Regulation ("Regulation") states:

(1) A permanent anchor for a rope access system must have an ultimate load capacity, in any direction in which the load may be applied, of at least 22.2 kN (5 000 lbf) for each person connected to the permanent anchor.

(2) In addition to the requirement under section 34.10(b) and in accordance with sections 7.3.2, 7.3.3 and 7.4, as applicable, of CSA Standard Z91-02 (R2013) Health and Safety Code for Suspended Equipment Operations,

(a) a permanent anchor for a rope access system must be inspected, at least once a year, and tested, and

(b) the results of the inspection and testing must be documented.

(3) A permanent anchor for a rope access system, and its installation, must be certified by a professional engineer.

(4) Subsections (2) and (3) do not apply to a permanent anchor for a rope access system used in the course of mountaineering or caving.

Purpose of guideline

This guideline clarifies the regulatory requirements for the inspection and testing of permanent anchors (anchors are also called anchorage connectors) used as part of a rope access system.

Anchor inspections

Section 34.10(a) of the Regulation specifies that equipment used for a rope access system, including anchors, must be inspected for defects by a person intending to use the rope access system before the system is first used on each work shift.

Section 34.10(b) of the Regulation specifies that the equipment must also be inspected in the manner and at the frequency required by the manufacturer of the equipment. The manufacturer may require daily, periodic, and regular inspections; these inspections are also a requirement under the Regulation. Note that section 9 of CSA Standard Z259.15-12 Anchorage Connectors specifies that each anchorage connector offered for sale include recommended frequencies and procedures for inspection and maintenance.

CSA requirements for inspection and testing of permanent anchors

Section 34.12(2) of the Regulation refers to CSA Standard Z91-02 (R2013) Health and Safety Code for Suspended Equipment Operations ("Standard"), sections 7.3.2, 7.3.3, and 7.4. These sections of the Standard address the scope and frequency for anchor system inspections. They also describe reporting requirements and a special case where testing is required. The details of clauses 7.3.2, 7.3.3, and 7.4 are to be found in the Standard. In summary, the Standard specifies the following:

- Anchor systems need to be inspected every 12 months, if not more frequently

a) compliance of the design to current applicable standards and regulations

b) adherence of the anchor system itself to the design requirements i.e., engineered drawings

c) signs of distress in the exposed, visible, and accessible anchor system components

d) all adhesive and expansion fasteners

- A professional engineer must ensure the following:

a) prepare a report on inspections, findings, and recommendations

b) provide the building/equipment owner with signed and sealed inspection reports

- The equipment log must show the results of all inspection, testing, and servicing; all reports prepared by a professional engineer must also be filed with the equipment log

- If the anchor system uses adhesive or expansion fasteners, then each anchor requires load testing at least every five years in accordance with specifications outlined in the Standard. This test must be witnessed and documented by a professional engineer or a qualified person under his/her direct supervision