Proximity detection technology helps workers stay safe

Being struck by a piece of moving machinery can lead to loss of life or serious injury.

By Sarah Ripplinger

In British Columbia's construction industry, time-loss claims and serious injury rates are higher than those of all other sectors in the province. Around 19 percent of injuries in construction were considered serious.

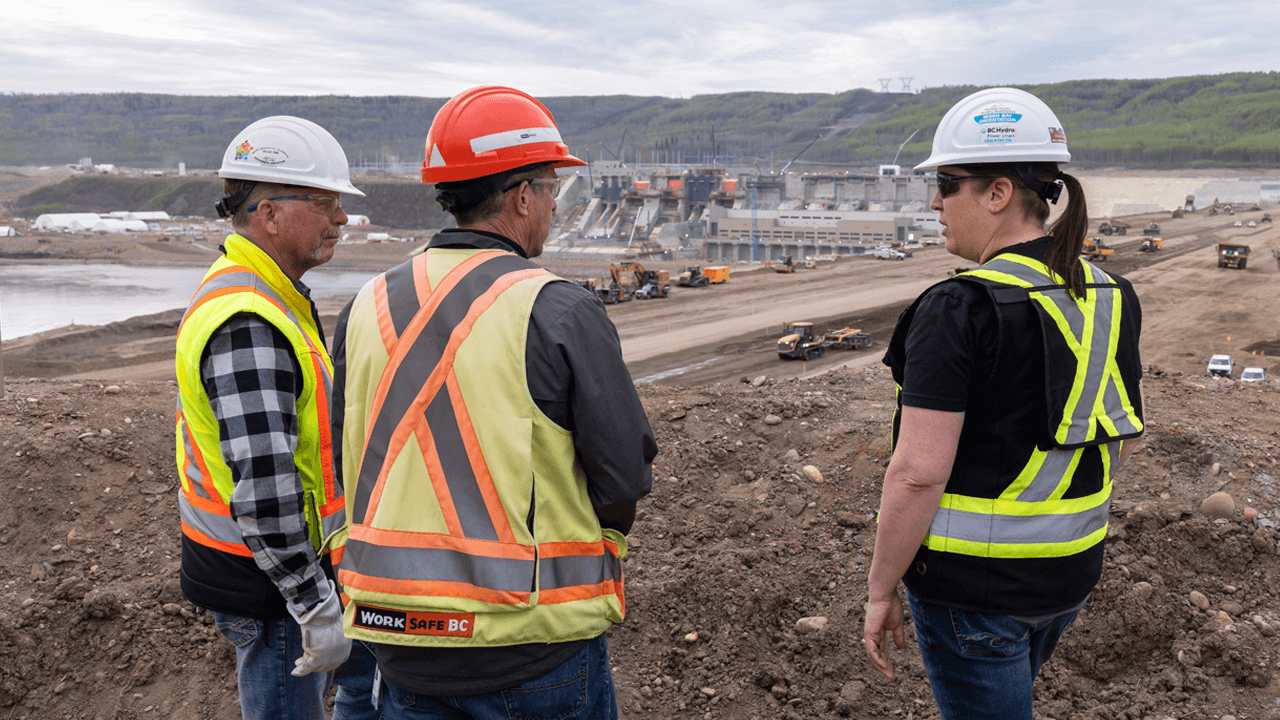

Peace River Hydro Partners (PRHP) — representing a partnership between ACCIONA Infrastructure Canada Inc. and Samsung Renewable Energy Inc. — have taken this safety risk to heart. They're implementing radio frequency identification (RFID) technology for their work on BC Hydro's Site C Clean Energy Project.

The Site C dam and generating station is currently under construction on the Peace River in northeastern B.C. As the primary civil works contractor for Site C, PRHP is constructing the earthfill dam, as well as other project components.

This poses a higher risk of a "struck-by" incident, which is when machinery comes into contact with a worker. Struck-bys are a leading construction workplace incident that can result in serious injury or death.

In B.C., around 550 struck-bys occurred in the past 10 years alone.

RFID technology warns operators when workers are nearby

To help protect the health and safety of up to 1,500 workers involved in its part of the Site C project, PHRP implemented the SCAN~LINK system.

This involves inserting RFID tags into workers' hard hats. Receivers are then mounted on machinery.

"Workers cannot always notice, see, hear, and respond to all the challenges around them," says PRHP health and safety director, Marina Gasmann. "Workers engaged in and focused on a task have even less ability to pay attention to changes around them. They might not notice people or vehicles approaching."

The SCAN~LINK system provides an audible alert to machine operators whenever a ground worker wearing an RFID-tagged hard hat comes within the danger zone of 15 feet, explains Gasmann.

PRHP mounted a single-node receiver on smaller equipment used during the project, such as smooth drum rollers (also known as packers and dozers).

Larger excavators and tractors that have more blind spots were mounted with a dual-node receiver for an increased detection zone. The technology was not installed on haul trucks as they already have camera systems and primarily move in a forward motion where the presence of ground personnel is minimal, Gasmann explains.

Test run a success with workers

In 2022, PRHP ran a trial of the SCAN~LINK system on 22 pieces of equipment with 50 workers outfitted with RFID-equipped hard hats.

Ground workers wore orange hard hats to identify them at a glance. Supervisors wore white hard hats with a sticker stating that it was RFID-equipped, adds Gasmann.

"We talked about this technology with workers at length — in joint health and safety committee meetings, at toolbox talks, and during the trial," says Gasmann. "Almost all the feedback we received from workers was positive."

Each worker completed a survey at the end of the trial. In one survey response, a worker shared that the technology provided "added security knowing that operators I work around will know I am close by." Another noted that: "as a surveyor, we are out with equipment all day. It helped us be identified when working around equipment."

Initiative for planned inspections in the construction industry

WorkSafeBC occupational safety officer Scott McInnis says the use of RFID equipment aligns with the broader Construction Planned Inspectional Initiative. This initiative was launched in 2023 to reduce serious injury and time-loss claims. The approach is designed to ensure the most significant risks in construction are effectively managed.

"It brings together workers and employers to identify hazards and evaluate risks. Then they implement the appropriate controls specific to on-site activities," McInnis states.

Employers need to communicate risk-minimizing strategies to workers and monitor their implementation.

This should be done through health and safety systems built into the workplace, such as worker orientations, training, supervision, incident investigations, worksite inspections, and joint health and safety committees.

Another part of the initiative is to reduce the frequency of struck-bys from mobile equipment and vehicles. This part of the initiative focuses on using the hierarchy of controls.

"The hierarchy of controls is a risk-based approach to hazards such as mobile equipment," says WorkSafeBC ergonomist Heather Kahle. "Employers should use the hierarchy of controls to maximize their hazard reduction strategy."

Hierarchy of controls as part of a risk-based approach

The hierarchy of controls is an essential tool for employers to correct unsafe workplace conditions. Employers should address the greatest risks first. They should either eliminate the hazard associated with that risk or apply the best possible approach to reduce it.

If it's impossible to eliminate a hazard, employers should move to the next control in the hierarchy. Lower levels of control measures are the least protective, but they can work in combination with another type of risk control to reduce the risk.

- The most effective control in the hierarchy is elimination, or the removal of the hazard.

- The second is substitution, or replacing the hazard with a safer approach.

- Engineering controls are next in the hierarchy. These controls include things like gates or barriers that help isolate workers from hazards.

- Administrative controls are the next level of control. These controls, such as RFIDs, include warning systems, and safe work policies and procedures.

- The least effective level of control, but still essential, is personal protective equipment (PPE). Examples include hard hats, protective eyewear, and safety vests.

RFIDs provide an added tool in the toolbox when the hazard cannot be eliminated, substituted, or engineered, notes McInnis.

"Workers feel more comfortable when we introduce the use of RFIDs into the field," says Gasmann. "Workers also get excited about new technology that addresses hazards."

"And if workers feel that their employer is investing in their safety and using leading edge technologies, workplace safety culture almost always improves."

Some other considerations for RFID technology

In some circumstances, RFID technology may not be practical. Confined or congested work areas can result in alarming the system. Workers get acclimated to the alarm to the point where they may no longer react to it.

"In such circumstances, we may restrict entry to a work area where equipment is operating in a tight or congested environment. We can also designate a spotter, and install more cameras within the cab of the equipment to improve the operator's line of sight," Gasmann explains.

"As we all know, technology has its limitations. For this reason, the message to employees has always been that the RFID system is not to be relied upon solely."

PRHP instructs employees to follow a "50/10 rule of approach." This means ground personnel must make eye contact with an equipment operator and wait for positive confirmation by the operator when 50 metres from the equipment. When a worker reaches 10 metres distance from larger machinery, the operator must stop the equipment, ground all implements, and exit the cab. Only then can the ground personnel approach the last 10 metres.

Moving forward with tracking on other machinery

Following the trial period, PRHP expanded to 30 units equipped with the SCAN~LINK systems. They focused on tracked equipment and rollers operating on the core at the centre of the dam. This equipment can move in various directions, and may have swinging parts that can pose a greater risk to ground personnel, notes Gasmann.

"PRHP made the decision based on the protections the system would offer, not the cost," says Gasmann.

To date, PRHP has invested roughly $200,000 in the system and continues to install it not only on their owned equipment, but also on any rented equipment.

"A few of us approached our project management team with this available technology and the response was: ‘let's see if it works and then go for it'," recalls Gasmann. "Our management team has been very focused on reducing risks associated with the construction activities we are completing this year. Struck-by incidents were consistently highlighted as our biggest hazard when we conducted our hazard analysis."

"To have this type of technology that can help decrease or even eliminate these types of incidents makes it difficult to turn the other way," says Gasmann. "It would be excellent to see some of the large equipment manufacturers integrate these systems into their equipment."

To learn more, visit our Construction Planned Inspectional Initiative webpage. You can also learn more about hazard identification, risk assessment, and the hierarchy of controls on our Managing risk webpages.

This information originally appeared in the Summer 2023 issue of WorkSafe Magazine. To read more or to subscribe, visit WorkSafe Magazine.